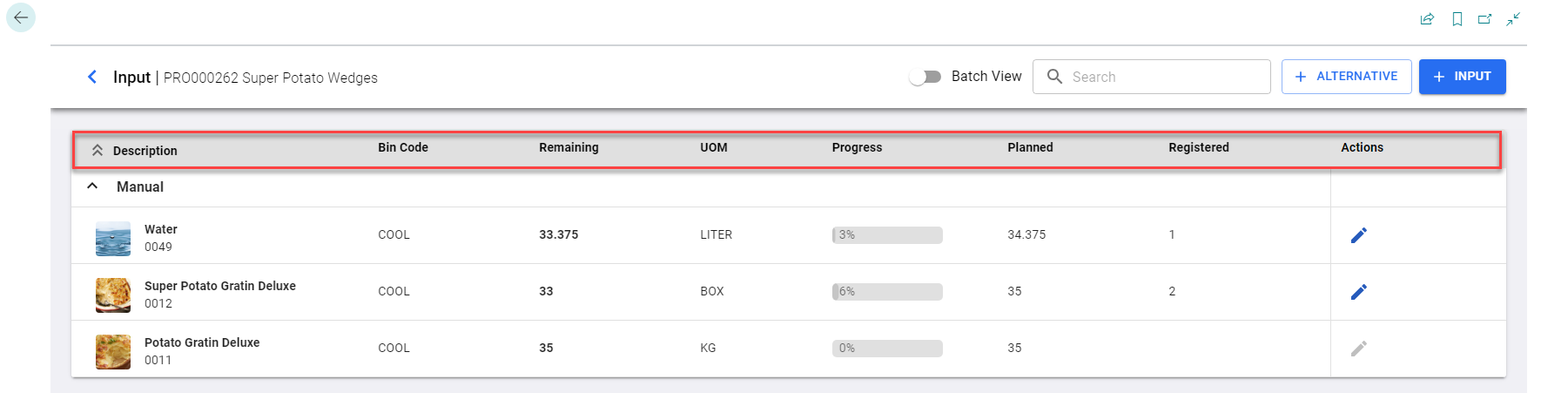

Registration of input

You can register the input for the production order in the shop floor production. The Input page displays all the items from the BOM associated with the production order.

Select the Input cues on the production order.

This cue provides the percentage of the input items registered for the production order and flushing method associated with it.

On the Shop Floor Production page, the component lines are consumed based on their flushing method, which is configured on the Item Card page and reflected in the production order component lines. Flushing methods are broadly classified into:

- Manual: Requires input registration by the user.

- Automatic: Includes methods like backflush and consolidated consumption, which are handled through system processes.

Items marked for consolidated consumption are consumed through a batch process using the Calculate Consolidated Consumption page and are not eligible for manual registration. To improve visibility, such lines are displayed in the Automatic or Consolidated group on the Input page, similar to backflushed items.

The system displays “–“ on the Input tile when all items are set to automatic flushing, indicating 0% completion. If any items in the production order are set to manual flushing, the completion percentage will be calculated based on the registered input.

The automatic flushing method includes Backward, Forward, Pick + Forward, and Pick + Backward. As these are not used in input registration, the number of available items with the respective flushing method are displayed.

The Input page displays the following fields:

| Field | Description |

|---|---|

| Description | Specifies the description of the item. |

| Bin Code | Specifies the bin code associated with the production order component line. |

| Remaining | Specifies the remaining quantity of the item after registering the input. This is the difference between the Planned and Registered field values. When the registered value is greater than the planned value, the remaining field is updated as 0. |

| UOM | Specifies the unit of measure code based on the value of the Item Card page. |

| Progress | Specifies the progress of the production order as a percentage. The percentage is calculated by dividing the registered value by the planned value and then multiplying the result by 100. |

| Planned | Specifies the quantity of the item configured in the Quantity per field on the Production BOM page. This value is multiplied by the Quantity field on the respective production order. |

| Registered | Specifies the quantity of items registered on the Input page through the Input action. |

| Actions | Includes options to edit the input line. When you click the Edit icon, the Correct Consumption dialog opens, allowing you to modify the consumption details. The Edit icon is only accessible for items with the flushing method set to Manual. If no consumption has been recorded for an item, the Edit icon will be disabled. |

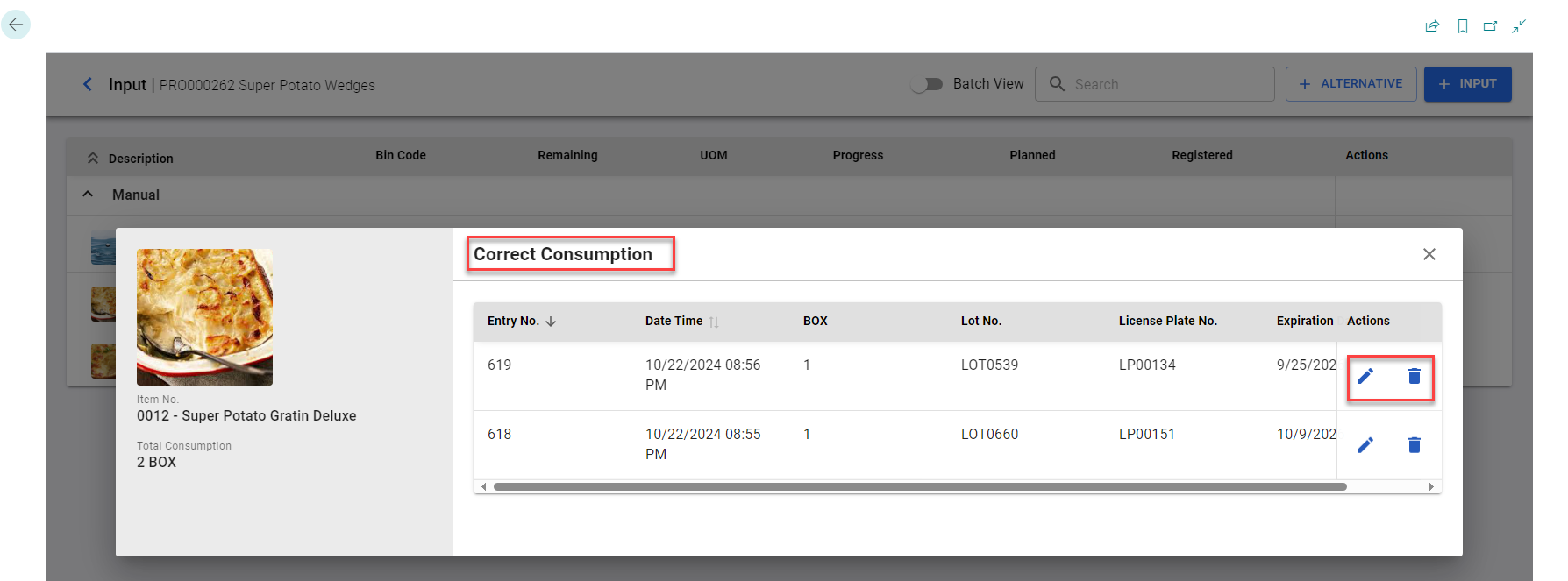

To correct consumption entries

You can correct consumption entries for manually flushed items. By selecting the Edit icon, you can view and manage all consumption entries, including deleting an entry (complete undo) or making specific edits.

Follow the steps below to correct the consumption entries.

- Open the Input page.

- Select the Edit icon.

The Correct Consumption dialog opens, displaying a list of all consumption entries for the selected item.

If only one consumption entry exists, the system automatically opens the Correct Consumption dialog.

Each entry includes the following options:

-

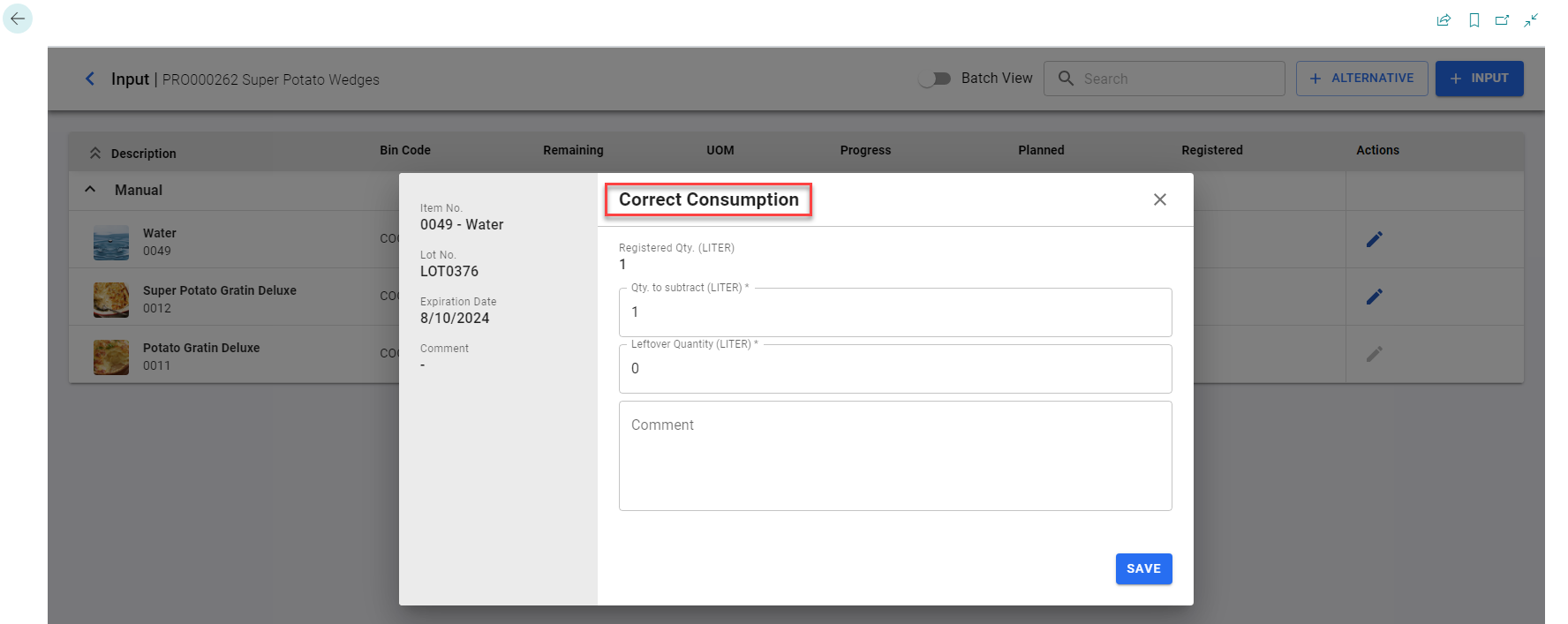

Edit icon: Select the Edit icon for the entry you want to modify. The system will open the Correct Consumption dialog for the selected entry, allowing you to update quantities and other details. The Qty. to Subtract field is automatically filled based on the original consumed quantity.

Additionally, in the Leftover Quantity field, you can enter the desired leftover quantity directly.The system sets the Leftover Quantity field to zero by default. You can update this field as needed, and the Qty. to Subtract field is automatically updated.

The Qty. to Subtract field automatically adjusts to reflect the change, ensuring Qty. to Subtract + Leftover Quantity = Total Quantity Consumed.

Corrections will automatically apply to the same license plate used in the original consumption entry for license plate-tracked items.

-

Bin icon: If you select the Bin icon, a confirmation message appears stating that the action will undo the entire consumption item ledger entry. If you proceed, the system creates a correction in the item ledger, fully reversing the selected consumption entry.

The license plate number, lot number, and expiration date details are automatically populated based on the item tracking setup.If you attempt to correct a quantity greater than the consumed quantity for the selected entry, the system will display an error message.

-

Select Save to apply the correction.

The system will validate the consumption correction for non-license plates (lot-tracked) items.

The system creates a new item ledger entry for the adjusted quantity and update the remaining, progress, and registered quantities on the Input list page.

When you select the ALTERNATIVE action, an Add Alternative Item dialog opens where you can add an alternative item for the items that are displayed on the Input page. You can also mention the quantity of the alternative item directly on the Input page.

This is applicable only when the Aptean Process Manufacturing extension is used in conjunction with the Aptean Shop Floor Production extension.

The system filters the component lines based on a single Routing Link Code field value defined on the routing lines on the Input tile, Item dropdown on the Register Input page, and Item to be replaced dropdown on the Add Alternative Item dialog.

You can perform registration of the input by selecting the Input action. You can also click any line on the Input page to perform the register input function.

You can perform the Input action only when the status of the selected production order is set to Production.

Register consumption for a license plate

To consume all items on a license plate, follow these steps:

-

On the Input page, select + LICENSE PLATE.

The Register License Plate window opens.

-

In the License Plate No. field, enter the desired license plate number.

You can specify how the system processes entire license plate consumption for production orders in the License Plate Consumption Mode field on the Shop FLoor Production Setup page.

-

Select SEARCH.

If the entered number is invalid or empty, the system displays an error message.

If the license plate is valid, the system displays the license plate details for each item on the license plate, including:

- Item No.

- Description

- Lot No.

- Quantity

- Unit of Measure

- Expiration Date

-

Review the list and select CONFIRM to proceed with consumption or CANCEL to exit without changes.

After you confirm:

- Each item on the license plate is registered individually.

-

If one or more items cannot be registered, those items are skipped. The system displays the items that failed to register along with the reason for each failure.

After processing is complete, the Input screen automatically refreshes to display updated quantities.

This functionality is not supported when using the Aptean Beverage Advanced Warehouse Management extension, Drink-IT Edition, is installed.

Correct consumption with AWM license plates

You can correct the consumption of license plate-tracked items onto a different advanced warehouse management license plate. This enables flexibility in handling inventory adjustments during consumption corrections.

- Make sure to configure the Aptean Beverage Advanced Warehouse Management for Drink-IT Edition application name on the Feature Control page. For more information, see Overview of feature control.

- Turn on the Allow New License Plate in Consumption Correction toggle on the Shop Floor Production Setup page.

- Configure the Adv. Warehouse Setup page and the Advanced Warehouse Management FastTab on the Item Card page. For more information, see Setup advanced warehouse management.

To correct the consumption with the advanced warehouse management license plates, follow these steps:

- Open the Input page for consumption.

- Select the required record.

The Register Input page opens. - In the License Plate No. field, select the required value.

The dropdown displays the available advanced warehouse management license plates. - In the Quantity field, enter the required quantity for consumption.

- Save the changes to register the input.

- Once registered, you can correct the consumption for the registered input line by using the edit icon.

The Correct Consumption page opens. - In the Qty. to Subtract field, you can modify the value to correct the consumption quantity.

- The To License Plate field displays the advanced warehouse management license plate number (original consumption license plate number) for which the input is registered.

- You can also execute the GET NEW LICENSE PLATE NO. action to generate a new advanced warehouse management license plate number for the corrected consumption quantity.

The system sends a request to Business Central to generate a new license plate number. - Select Save.

The system corrects the consumption onto the original license plate first.

If a new license plate is assigned, the system creates an item reclassification journal transaction to move the corrected quantity to the new license plate.

The journal entry uses the template specified in the Consumption Correction Reclassification Journal Template Name field on the Shop Floor Production Setup page.

You can view the created entries for the corrected consumption on the Detailed Warehouse Entries page.