Quality Control integration with Inspection Status

Creating Quality Alerts when changing the inspection status

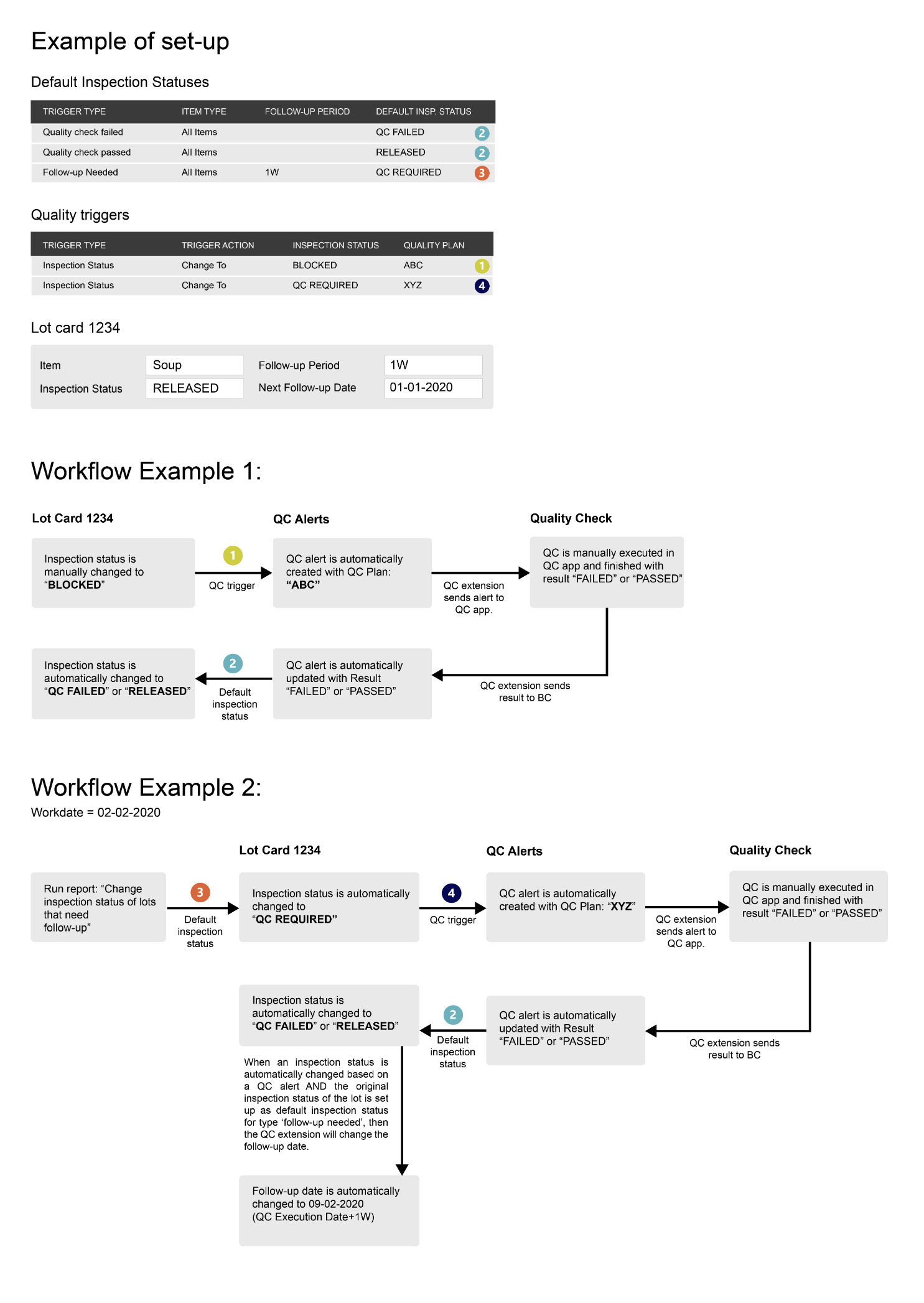

When a quality trigger is set up with the type ‘Inspection Status,’ a quality alert is created when the function ‘Change Inspection Status’ has been used in the Inspection Status extension (manually or automatically via another function). Only lot numbers that have been changed to the inspection status code which is set up as quality trigger apply to the quality trigger. Multiple quality alerts are created if the lot number has inventory on multiple locations, one quality alert for each location that has inventory of the lot number. All these alerts are assigned with the same Inspection Status Reference Number, so later on, it’s always possible to deduce which alerts originated from the same inspection status change. Locations set up as a ‘transit’ location are not included and won’t create a quality alert, because these lot numbers are in transit between locations.

When changing an inspection status for which a quality trigger has been set up, a quality alert is only created if no quality alerts with status 'Open' or 'In Progress' are already present for that item/variant/lot number.

This is to prevent quality alerts from being generated for two inspection status changes, whereby the quality alerts that are finished last ultimately determine the new inspection status of the lot (based on 'Passed' or 'Failed' and the associated default inspection status).

Change the inspection status when finishing the Quality Check

When the quality checks are executed and finished in the ‘Quality Check’ PowerApp, the related quality alerts are updated with the result ‘failed’ or ‘passed’. Via setup in the Inspection Status extension (trigger types ‘Quality Check Failed’ and ‘Quality Check Passed’ in Default Inspection Status) it is possible to change the inspection status of the associated lot number when finishing the quality check.

If the quality alerts are created based on a quality trigger of type ‘Inspection Status’, it is first checked if multiple alerts exist for this lot number due to inventory on multiple locations when finishing a quality check. If there are other alerts present with the same Inspection Status Reference Number with an open or in progress-status, the inspection status of the lot will not be changed yet. The inspection status will be changed when the status ‘Closed’ (or ‘Skipped’, ‘Deleted’) is assigned to all the alerts for the same Inspection Status Reference Number. In this latter case, when one or more of the alerts have a result ‘Failed’, the overall result will be failed. The inspection status of the lot will then be changed based on the setup in Default Inspection status with trigger type is ‘Quality Check Failed’. Otherwise the setup with trigger type ‘Quality Check Passed’ will be applied.

If the status of a quality alert is manually changed into ‘Skipped’ the system also checks if there are other quality alerts present with the same Inspection Status Reference Number as mentioned in the previous chapter. If there are other alerts present with the same Inspection Status Reference Number with an open or in progress-status, the inspection status of the lot will not be changed yet. The inspection status will be changed when the status ‘Closed’ (or ‘Skipped’, ‘Deleted’) is assigned to all the alerts for the same Inspection Status Reference Number. In this latter case, when one or more of the alerts have a result ‘Failed’, the overall result will be failed. The inspection status of the lot will then be changed based on the setup in Default Inspection status with trigger type is ‘Quality Check Failed’. Otherwise, the setup with trigger type ‘Quality Check Passed’ will be applied.

If the quality alerts are created based on another quality trigger type, the inspection status will be changed immediately after finishing the quality check (based on the result of that quality check).

When an inspection status is automatically changed based on a quality alert and the original inspection status of the lot number is set up as default inspection status for the type ‘follow-up needed’, then the ‘Next Follow-up Date’ needs to be recalculated and changed as well. This field specifies the date on which the next follow-up on the lot should be executed. For more information, see the manual of the Inspection Status extension.