Weight and Yield Percentage

The total weight of the Production BOM (expressed in the setup Weight Unit and based on the unit of measure registered on the Production BOM) can be calculated on the header of the Production BOM page.

To do this, the following calculations are made at the Production BOM line level:

- The type of weight that is taken into consideration (net weight or gross weight).

- The weight represented by the specific BOM line level before the production process (identified as the Input Quantity per WU) is expressed in the unit of measure of the Production BOM line.

- The weight represented by the specific BOM line level after the production process (identified as the Output Quantity per WU) is expressed in the unit of measure of the Production BOM line.

These fields will be summarized on the Production BOM header level to give insight into the total net- and gross weight of one produced unit (in the unit of measure of the Production BOM). Also, from these figures, the Yield% is calculated.

Weight and Yield Setup

- Navigate to the desired Production BOM page.

- On the Lines FastTab, in the Weight Calculation Type field, select Net Weight.

The options in the Weight Calculation Type field are Net weight, Gross Weight, and BOM Weight. - On the Production BOM page, on the action bar, select Actions > Other > Calculate Weight and Yield.

The action has calculated the weight for the production BOM lines for which the Weight Calculation Type field has been filled as follows:

- In each production BOM line, the Input Quantity per (WU) field unit specifies the weight represented by the specific BOM line before the production process has taken place, expressed in the Unit of Measure of the Production BOM line.

- In each production BOM line, the Output Quantity per (WU) field specifies the weight represented by the specific BOM line level after the production process has taken place, expressed in the Unit of Measure of the Production BOM line.

When the Dynamic BOM Line Weight Calculations toggle on the Process Manufacturing Setup page is turned on, the system automatically calculates input and output weight field values. For more information, see Process weight change percentage on production BOM lines.

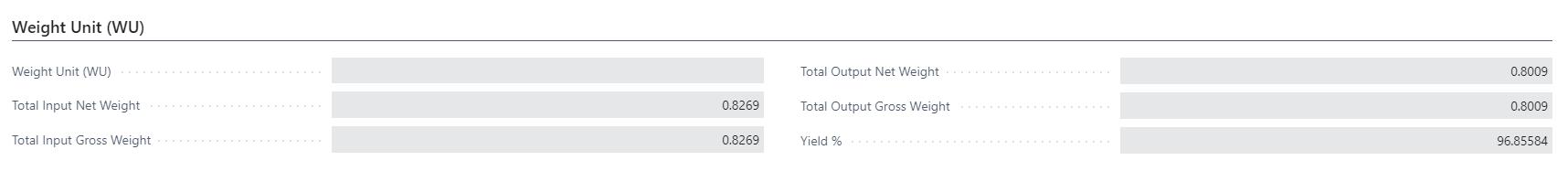

The action has calculated the Weight and Yield for the Production BOM header as follows:

- The Total Input Net Weight field specifies the sum of the value of the Input Quantity per (WU) field of all Production BOM lines where Weight Calculation Type = Net Weight.

- The Total Input Gross Weight field specifies the sum value of the Input Quantity per (WU) field of all Production BOM lines where Weight Calculation Type = Net Weight or Gross Weight.

- The Total Output Net Weight field specifies the sum value of the Output Quantity per (WU) field of all Production BOM lines where Weight Calculation Type = Net Weight.

- The Total Output Gross Weight field specifies the sum value of the Output Quantity per (WU) field of all Production BOM lines where Weight Calculation Type = Net Weight or Gross Weight.

- The Yield % field specifies the yield percentage, which is calculated by dividing the value of Total Output Net Weight by the value of Total Input Net Weight on the Production BOM header.

The Weight and Yield% are also automatically calculated upon certifying the BOM.

Weight Calculation Type

The Weight Calculation Type field is updated with the option based on the selection of Production BOM Type on the Lines FastTab of the Production BOM page. The line type of the Production BOM can be Item or Production BOM.

- When the Type field is selected as Item, the Weight Calculation Type field is inherited with the value from the Default Weight Calculation Type field on the Item Card page.

- Navigate to the desired Item Card page.

- On the Replenishment FastTab, in the Default Weight Calculation Type field, select an option from the dropdown.

This value is inherited in the Weight Calculation Type field on the Lines FastTab of the Production BOM page, when the item is selected on the Type field.

- When the line is set up with the type Production BOM, the weight calculation type is automatically set to BOM Weight, indicating that the weight calculation types of the underlying BOM lines should be used to determine in what category they fall.

You can change the Weight Calculation Type field value manually when required.

Process weight change percentage on production BOM lines

On the Production BOM page, on the Lines FastTab, the Process Weight Change % field specifies the percentage of weight lost or gained for a component during manufacturing. This value impacts the following fields:

- The Output Quantity per (WU) field for lines with the Batch Size checkbox cleared.

- The Output Quantity per Batch and Output Quantity per Batch (WU) fields for lines with the Batch Size checkbox selected.

The calculation method depends on the configuration of the Dynamic BOM Line Weight Calculations toggle on the Process Manufacturing Setup page.

The Output Quantity Per Batch and Output Quantity Per Batch (WU) field values are more precise due to enhanced rounding calculations.

These values are rounded to five decimal places on the Production BOM page for improved accuracy.

When this toggle is turned on, and the Weight Calculation Type field on the production BOM line is set to Net Weight or Gross Weight, the system dynamically calculates and updates the following fields:

Input Quantity Per (WU)

The Input Quantity Per (WU) field value is calculated based on the values in the Quantity Per WU and Scrap % fields.

Input Quantity Per (WU) = Quantity Per WU + (Scrap % x 0.01 x Quantity Per WU)

For batch size lines, if the Input Quantity per Batch or Input Quantity per Batch (WU) field value is modified, the Input Quantity per (WU) field value is reset to 0 and only updates after executing the Calculate Quantity per action.

Output Quantity Per (WU)

The Output Quantity Per (WU) field value is calculated based on the values in the Quantity Per WU and Process Weight Change % fields.

Output Quantity Per (WU) = Quantity Per WU + (Process Weight Change % x 0.01 x Quantity Per WU)

For batch size lines, if the Output Quantity per Batch or Output Quantity per Batch (WU) field value is modified, the Output Quantity per (WU) field value is reset to 0 and only updates after executing the Calculate Quantity per action.

Process Weight Change %

The Process Weight Change % field value is calculated based on the values in the Quantity Per and Output Quantity per (WU) fields.

Process Weight Change % = [Quantity Per x (GetFactorUOMWeightUom – Output Quantity per WU)/ (0.01 x Quantity Per x GetFactorUOMWeightUom)] x -1

The GetFactorUOMWeightUom value is calculated by dividing the Qty. per Unit of Measure field value for the item’s base unit of measure by the Qty. per Unit of Measure field value for the item’s unit of measure specified in the Weight Unit (WU) field on the Process Manufacturing Setup page.

The changes to these fields will also dynamically update the related fields based on the calculations.

Changes to Yield % field on the production BOM line

The Yield % field on the production BOM line has been replaced with the Process Weight Change % field in the Aptean Process Manufacturing, version 2412.0.0.0. The existing records with the Yield % field values are converted using the formula:

Process Weight Change % = Yield % - 100

For example, if Yield % = 80, then Process Weight Change % = 80 – 100 = -20.

If the Yield % field value is 0, the system directly updates the Process Weight Change % field to 0 without using the formula.