Order commitment

The Order Commitment page gives insight into which Sales Order Lines still need to be planned for production. The page gives the option to directly create a production order so that the open demand from the sales order can be met. This will create an order commitment that allows you to reserve production output inventory for the specific sales order.

- Select the Search icon

,enterOrder Commitment, and then choose the related link.

,enterOrder Commitment, and then choose the related link.

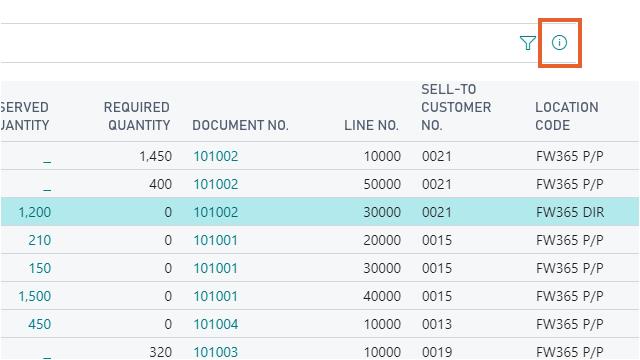

The Order Commitment page opens.

The first columns on the Order Commitment page shows the information from the sales order. The page only shows sales order lines with outstanding quantity and items that are set up with Replenishment System as Production Order, implying that the item is replenished by producing the item. The item must also be set up with a Reordering Policy as Order, implying that the item is specifically planned for each demand. Both fields can be set on the item card.

The table describes the fields of the Order Commitment page.

| Field | Description |

|---|---|

| Outstanding Quantity | Specifies how many units on the sales order line have not yet been shipped. |

| Reserved Quantity | Specifies how many units of the item on the sales order line have been reserved. |

| Required Quantity | Specifies how many units of the item are required on the sales line. The required quantity is equal to the outstanding quantity minus the reserved quantity. |

| Document No. | Specifies the number of the document. When clicking the number, the Sales Order is opened directly. |

| Line No. | Specifies the number of the line of the Sales Order. |

| Sell-to Customer | Specifies the number of the customer who will receive the products. |

| Location Code | Specifies the inventory location from which the items sold should be picked and on which the inventory decrease is registered. |

The filter makes it possible to show only sales order lines that contain a required quantity, which implies that they still need to be planned for production.

- Turn on the Show only sales lines with a required quantity toggle.

Reserve Available Inventory

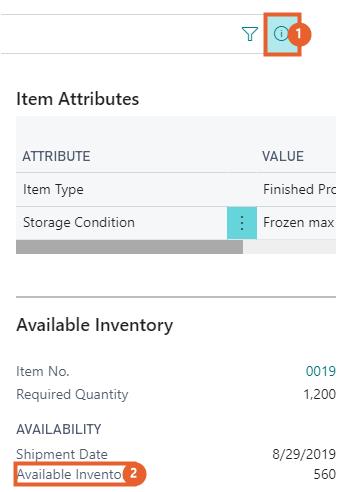

If there is available inventory for the item of a sales line, the user can decide to reserve the available inventory. Therefore, the available inventory is shown in the FactBox.

The Available Inventory specifies the quantity of the item that is currently in inventory and not reserved for other demand.

When selecting a Sales Order Line that contains an item with Available Inventory, a notification is shown to point this out.

- Select the required line on the Order Commitment page.

- Select the Open Reservation Page action on the notification on top of the page.

Alternatively, select the Reserve action on the action bar on the Order Commitment page.

The Reservation page opens.

Each line on the Reservation page displays information about one type of line (sales, purchase, journal) or inventory entry. The lines describe how many items are available to be reserved from each type of line or entry.

- Select the required line.

- On the action bar, click Actions > Functions > Reserve from Current Line or Auto Reserve.

- Click Close.

The Reserved Quantity field on the Order Commitment page is now updated with the quantity that has just been reserved.

Click the value on the Reserved Quantity field to open, the reservation entries . This shows how many items are reserved for which sales order and from which document they are reserved. From this page, you can cancel the reservation.

Create or cancel a reservation

It is possible to make new reservations or cancel an existing reservation.

- Select the Reserve function on the action bar on the Order Commitment Page.

The Reservation page opens. - On the action bar, select Actions > Functions > Cancel Reservation from Current Line field.

- Click Close.

There are now 560 items reserved from the Available Inventory. However, this is not enough to meet the outstanding number of 1200 items, because there are still 640 items that need to be planned.

Create a Production Order

To meet the required quantity, a production order can be created directly from the Order Commitment page for the selected sales order line.

- Select Create Prod. Order action on the Order Commitment page.

A dialog box appears and displays the following information:

Do you want to create a production order for this sales order line. - In the Prod. Order Status field, select the order type you want to use for creating the production order.

- Select Yes to create the production order.

The production order is now created for the required quantity.

Since the required quantity has now been met by creating the production order, the field Required Quantity has dropped to 0.

Order Tracking

Order tracking shows how the sales order is related to the production order through the planning and reservation systems.

- Select Order Tracking action from the Order Commitment page.

The lines in the Order Tracking display the documents that are related to the current sales order line. In this example, two item ledger entries and a released production order line are reserved for the sales order line. - Select the desired No.

- Click the Show field.

This opens the production order for which the output is reserved for the sales order line.

Filter Order Commitment on Item Attribute

The Order Commitment page can be filtered on Item Attributes.

- Select Filter by Attributes action on the Order Commitment page.

- Select the Attribute and the Value to specify additional filters on the Filter Items by Attributes page.

The Order Commitment now only shows sales order lines with items that contain the Item Attribute Value. - Select the action Clear Attributes Filter on the Order Commitment page.