Over-picking

The over-pick function enables the pick of more than the needed quantity without increasing the original quantity.

Registering more than the needed quantity in a production order without increasing the original quantity is possible in a warehouse- or inventory pick. When registering an over-pick via a production journal or consumption journal, the checks concerning the allowed over- and under-pick are not executed.

It is possible to change an item in the component line with the "Select Item Substitution" function. The settings for over- and under-picking are copied to the BOM line with the substituted item.

Over-pick in Inventory Pick

- Select the Search icon

, enter Inventory Picks and then choose the related link.

, enter Inventory Picks and then choose the related link.

The Inventory Picks list page opens. - Click the required No. to open the Inventory Pick card page.

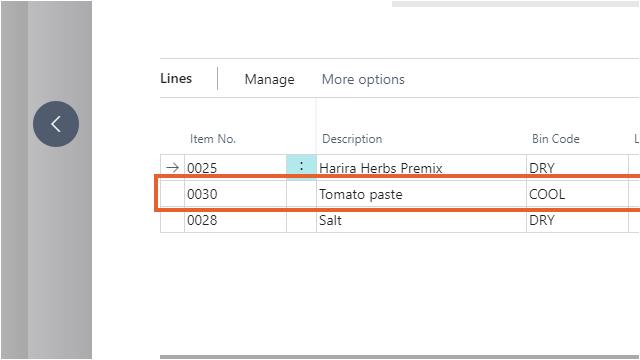

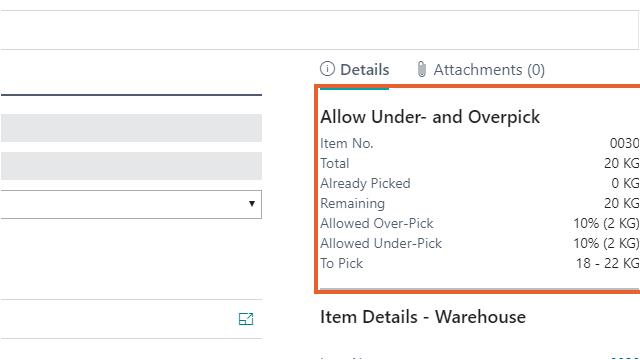

- On the Lines FastTab, select a line to see the allowed over- and under-pick in the Factbox.

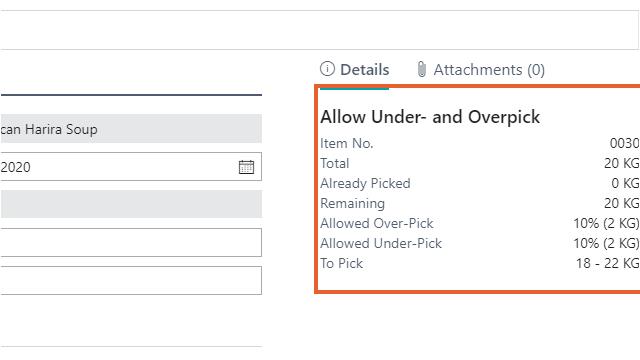

The factbox shows if under- and over-pick is allowed for the selected pick line. The percentage allowed over- and under-pick is calculated on the total of the component line. If the component line is split into several pick lines, the total of the component line is still shown in the factbox.

For example, if a component line with a quantity of 100 is split into two picklines where the allowed over-pick percentage is 10%, it is possible to register on the first picklines 90 and the second pickline 20, so that the total of the component line comes to 110. If the entered quantity to pick is outside the range, an error is shown.

If unlimited over- and under-pick is allowed, no percentages and range are shown.

-

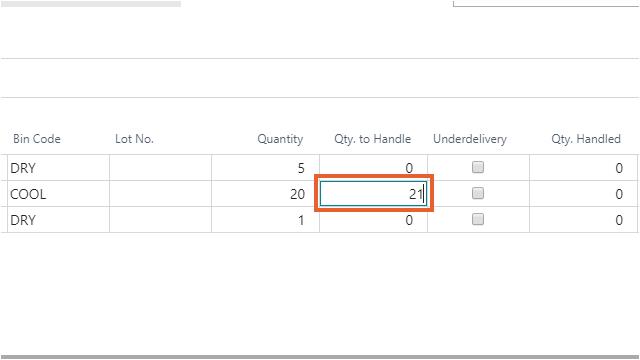

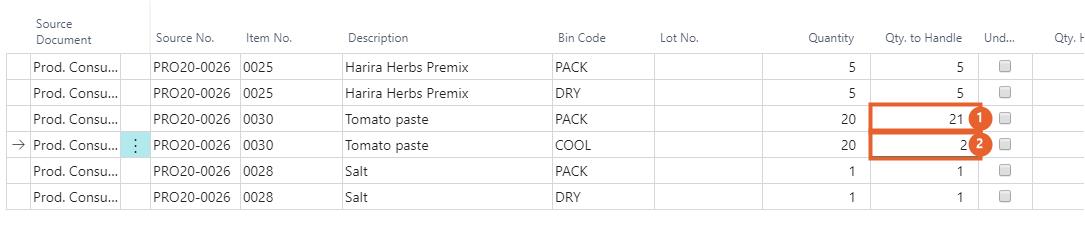

Enter a value in the field Qty. to Handle.

In this example, the quantity to pick is greater than the original quantity and the allowed over-pick percentage is 10%.

-

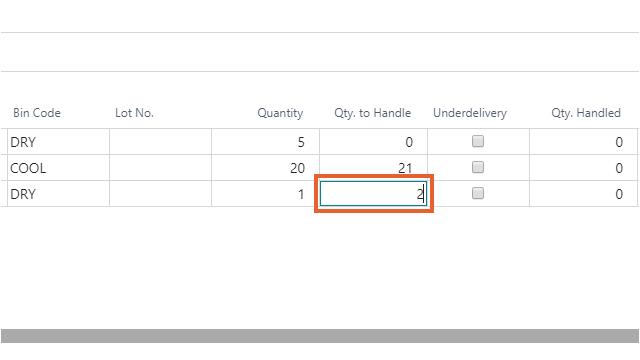

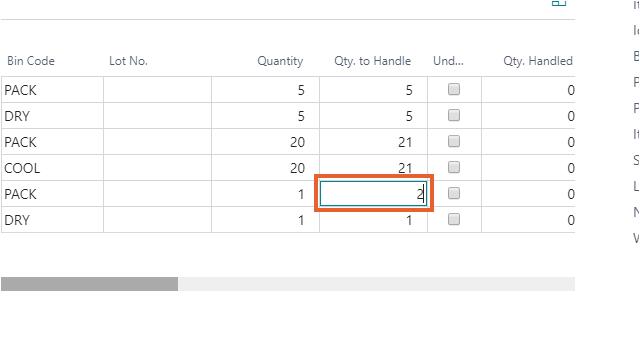

Enter another value in the next line in the field Qty. to Handle.

In this example, the quantity to pick is greater than the original quantity and the allowed over-pick in unlimited.

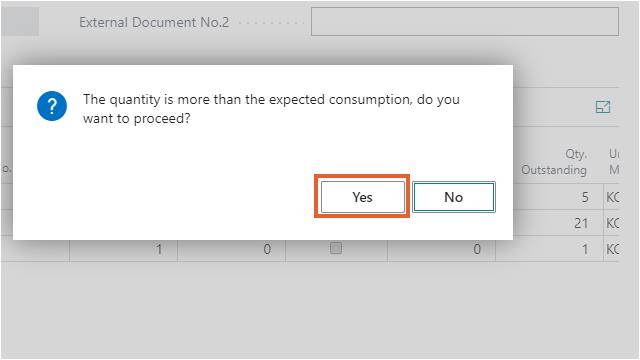

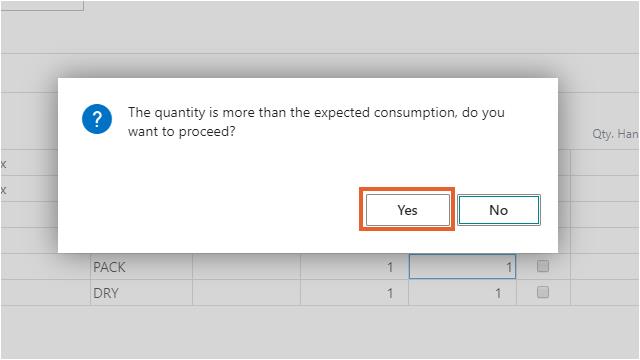

A confirmation message is shown to verify if this quantity is correct because the allowed over-pick is unlimited for this line.

-

Assign a lot number in the Lot No. field.

The lot number is assigned to the quantity that is entered in the field Qty. to Handle.

- On the action bar, click Posting > Post.

- Click Yes in the confirmation dialog box, "Do you want to post the Invt. Pick and Prod. Consumption?"

The inventory pick containing the over-pick is now posted.

Visibility over-pick after inventory pick

The picked quantity is shown on the Prod. Order Components page. The quantity with over-pick is used as the actual consumption.

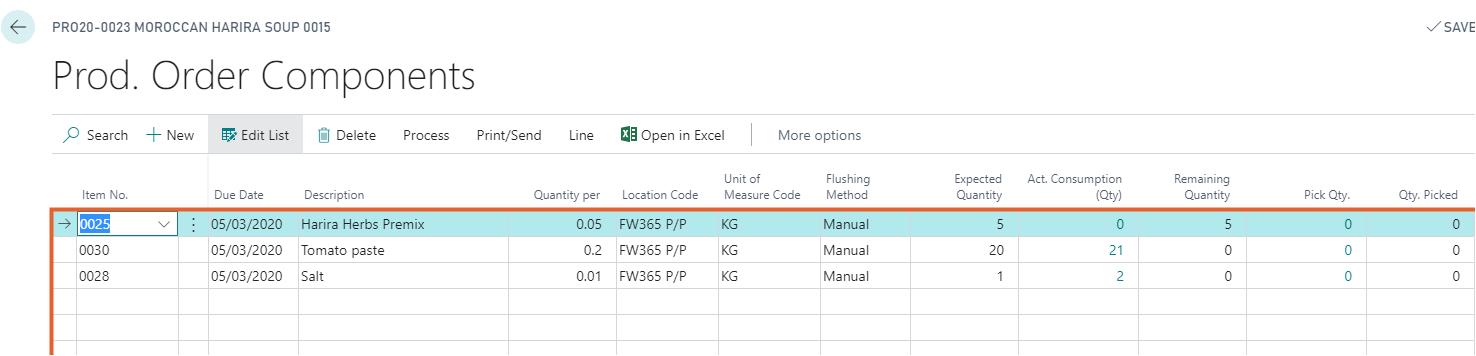

The field "Production Pick Variance" on the Prod. Order Components page shows the difference between the actual consumption and quantity. The pick variance will be recalculated after changing the "Quantity Per" in the component line.

Over-pick in Warehouse Pick

When a warehouse pick is used for picking components of a production order, the consumption has to be posted afterwards via a production journal or consumption journal. The quantity in the journal line is filled per default with the remaining quantity of the component line. when over-picking, the quantity in the journal line is filled with the picked quantity minus the already posted quantity for consumption.

For example: if the original quantity for the component line is 100 but 105 units are picked, then in the journal line (when consuming the component line) the quantity of 105 must be registered.

- Select the Search icon

, enter Warehouse Picks and then choose the related link.

, enter Warehouse Picks and then choose the related link.

The Warehouse Picks list page opens. - Select the required No. to open the Warehouse Pick card page.

-

On the Lines FastTab, select a line to see the allowed over- and under-pick in the factbox.

The factbox shows if under- and over-pick is allowed for the selected pick line. The percentage allowed over- and under-pick is calculated on the total of the component line. If the component line is split into several pick lines, the total of the component line is still shown in the factbox.

For example, if a component line with a quantity of 100 is split into two picklines where the allowed over-pick percentage is 10%, it is possible to register on the first picklines 90 and the second pickline 20, so that the total of the component line comes to 110. If the entered quantity to pick is outside the range, an error is shown.

If unlimited over- and under-pick is allowed, no percentages and range are shown.

-

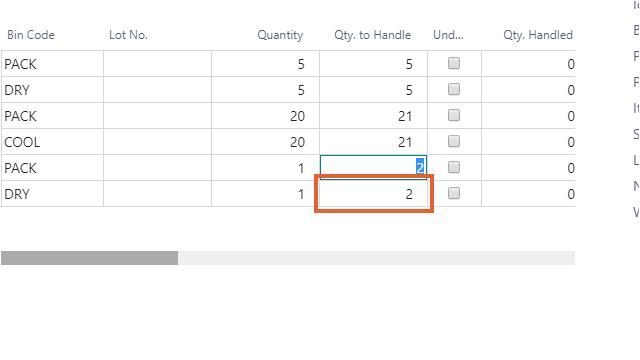

Enter the Qty. to Handle. In this example, the quantity to pick is greater than the original quantity and the allowed over-pick percentage is 10%.

The Qty. to Handle in the "Take" and "Place" line must be identical. The validation for over-picking is on the "Take" line.

-

Enter another value in the next line in the field Qty. to Handle.

In this example, the quantity to pick is greater than the original quantity and the allowed over-pick is unlimited.

A confirmation message is shown to verify if this quantity is correct because the allowed over-pick is unlimited for this line.

-

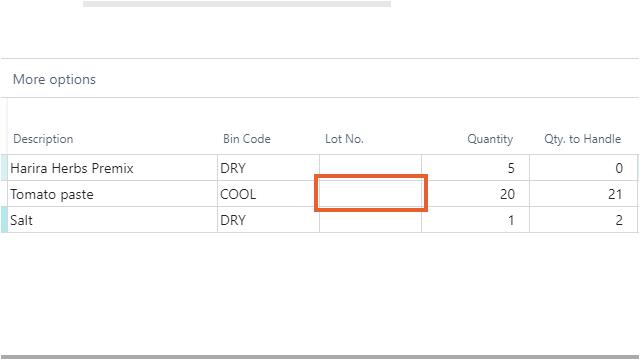

Enter Qty. to Handle.

-

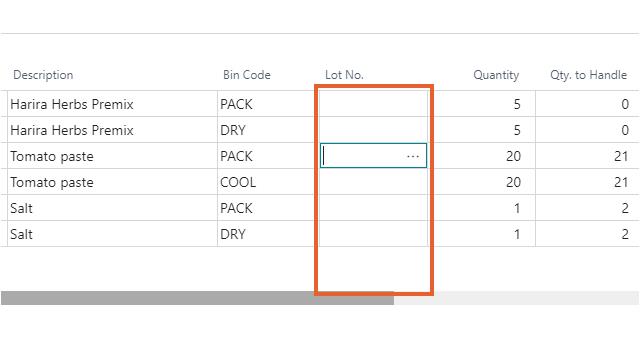

Assign a lot number in the Lot No. field.

The lot number is assigned to the quantity entered in the field Qty. to Handle.

- On the action bar, click Process > Register Pick.

- Click Yes in the confirmation dialog box, Do you want to register the Pick Document?

The warehouse pick containing the over-pick is now posted.

Visibility over-pick warehouse pick

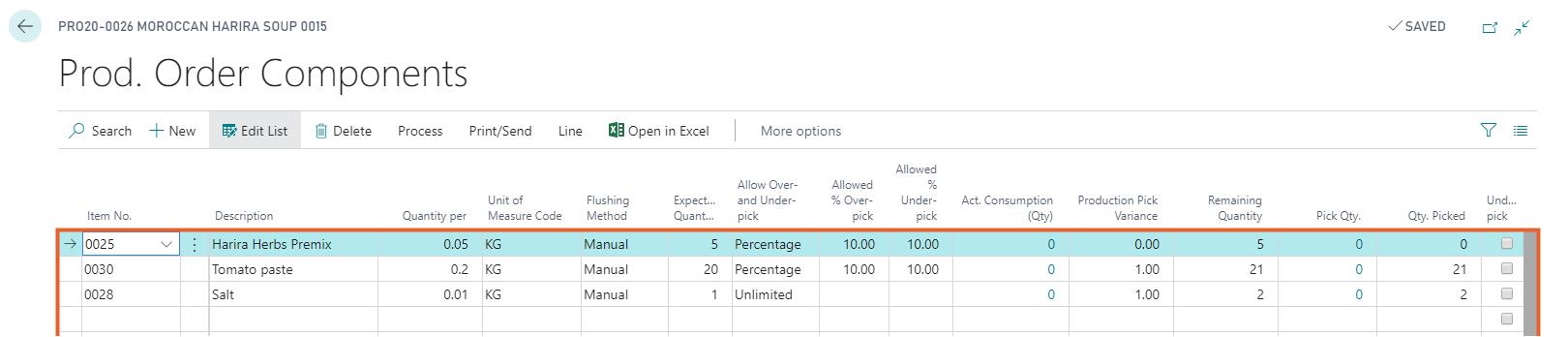

The picked quantity is shown on the Prod. Order Components page.

The quantity with over-pick is shown as picked quantity in the component lines via the production order. The "Production Pick Variance" field shows the difference between the picked quantity and quantity.

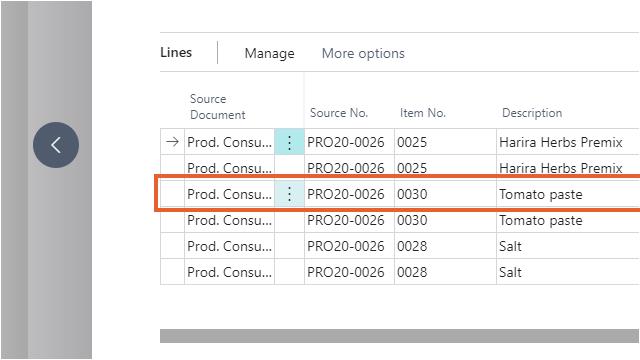

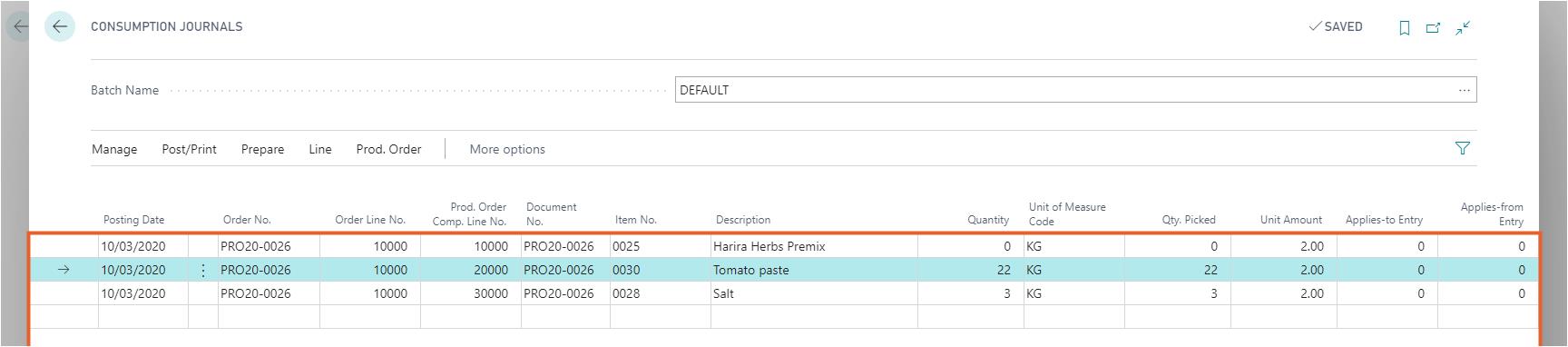

When a warehouse pick is used for picking components of a production order, the consumption has to be posted afterwards via a production journal or consumption journal. This image shows a consumption journal.

The quantity in the journal is filled with the picked quantity minus the quantity already posted for consumption.